Skills

Internal skills :

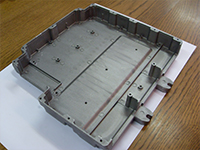

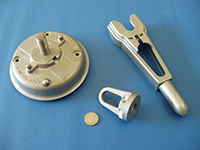

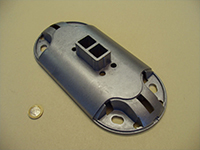

The foundry uses a process of transformation of metals which consists of pouring a liquid alloy into a steel mould to reproduce a defined part whilst limiting later finishing work as much as possible.

Among the different casting techniques, high pressure die casting is a quick and economic manufacturing process for production in large quantities of parts in lightweight alloys to finished dimensions and tight tolerances. His high repeatability is one of its major strengths.

DYNAFOND is equipped with all the current high pressure die casting techniques: vacuum casting, use of the chill vent, thermoregulation, etc.

The high pressure die casting process is supplemented by the presence of a cutting tool for separating the parts from the feed system. The parts cut in this way will then be able to follow different operations before the final packaging and delivery to the customer. Some of these operations are performed out and controlled internally: vibratory finishing or shot peening, simple machining operations or inspection.

DYNAFOND is also capable of supervising the work of external service providers to deliver a "turnkey" part following all the specifications and agreed deadlines.

In summary, DYNAFOND now offers you:

Economic production runs of medium and large series,

A value analysis making it possible to propose reductions in costs,

The manufacture of parts with complex shapes to finished dimensions,

A regular quality level for large volumes,

Blank castings obtained with narrow tolerances,

Long tool life duration.

Technical support to make your projects a reality (design/optimization of the part for the process).

The development of tooling: mould and cutting

External skills :

To propose complete sub-assemblies, DYNAFOND has been able to gather a network of efficient partners and sub-contractors in the following areas:

- Surface treatment

- Impregnation

- Painting

- Cataphoresis

- Bar turning

- Machining

- Polishing / Emerizing

- Inspection

- Electro-erosion

The responsiveness and adaptability of DYNAFOND also makes it possible to integrate new partners quickly to propose the best possible solution for its customers.